How a better edge for your laser cut parts makes you look good

Laser cutting has become critical in the supply chain for metal fabrication, and they have never been more productive.

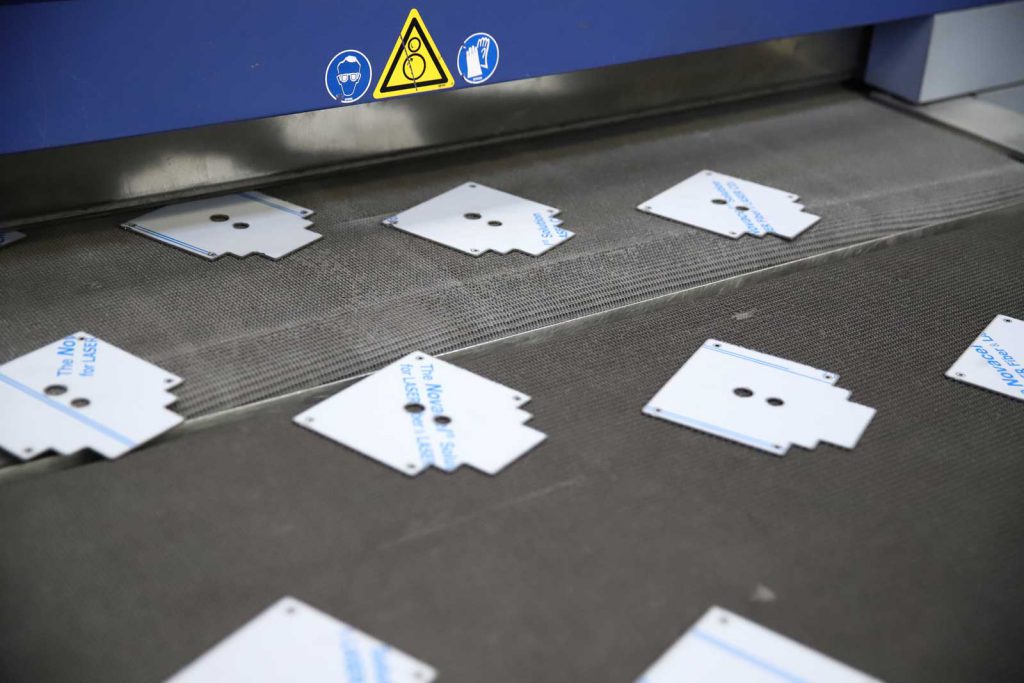

The laser finish and edge quality is, of course, subjective. A machinist will look at a laser-cut part and find that the edge quality is not very good. A welder, on the other hand, may look at the same part and see a smooth, consistent, high-quality edge. Regardless, the application requirements dictate what is considered a “quality” edge. A laser can finish a nest of parts in no time flat, but what if those parts need to be sent through a secondary edge rounding operation?

Cutting at so many inches per minute is great, but overall cycle time may not change much if parts get caught in an edge rounding bottleneck. To ensure a better cut edge, operators historically had to alter cut program parameters, such as the cut speed around sharp corners, but they sometimes found that this took longer than simply sending the entire run through an edge rounding system.

“We generally look for laser cutting services in Queensland, but we never knew you did that too.”

This is a line we often hear. However it’s rare to find a one-stop-shop for all your metal processing needs in Australia because most have downsized and moved into areas of specialisation. At Laser Central, we offer not only excellent laser cutting (tube and flat) and engraving services, we also offer edge rounding, fabrication, metal folding and many other processes and services.

The edge rounding services we offer are quite remarkable, allowing us to go over any potential imperfections and complete the job in an extremely professional way. This does not affect your lead times in any way, and give you a clean and neat look for your product. This in turn affects how you are viewed within your industry – a more professional looking product with no imperfect edges is seen as a superior product to its competitors. Contact us to know more about how your parts can benefit from our services.