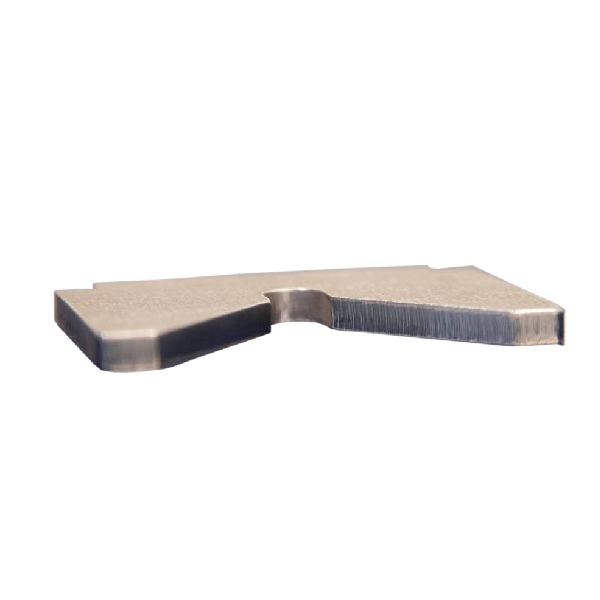

Services Edge Rounding

AS2312.2:2014 strongly recommends that all coated laser cut parts (both galvanised and painted) have their edges ground off. Indeed, painting services are demanding rounded edges in order to get a more even coating near edges and provide guarantees on work.

Laser Central takes pride in consistently and reliably applying our skills and forward-thinking approach to provide edge rounding services for mild steel and stainless steel. Moreover, we stand out in the market by offering this service for aluminium components, which is relatively rare.

WatchKey Capabilities

Process mild steel, stainless steel and aluminium

Contamination free, each metal treated with different media

Minimum size without jigging 150x50mm (smaller possible with jig and two passes)

Maximum part dimensions (the short axis will be less processed than long axis: 1500mm wide, 3000mm long and longer by special arrangement)

Thicknesses up to 50mm

Heavier radii possible with extra passes if required

Features

Compliance with AS2312.2:2014

Significant cost savings by re-deploying labour to more valuable processing

Superior product quality through consistent mechanical processing

Full part edge treatment, external and internal

OH&S risk reduction through reduced dust exposure