Our Valued Clients

Cutting-edge Industry Solutions

When it comes to all forms of laser cutting and sheet metal fabrication, our customers deserve the very best. When we form a partnership with your company, we make a commitment to provide you with unbeatable service and industry-leading quality every step of the way so you can solidify your own client relationships and blow your competition out of the water.

Case Studies

Laser Central is a business that invests in technology. I think we’re both companies that are extremely passionate about investing in equipment that allows our teams to go and build world-class products. I absolutely recommend Laser Central to other manufacturers.

- Zone RV

We’ve been working with Laser Central for many, many years now. They have the latest technology, with knowledge of automotive production requirements and the infrastructure to support us. In the early stages, they contribute to the design, they tell us what they can do, they tell us how to tweak things and then once the design comes into production we find that their support is second to none.

Laser Central has a lot of flexibility to achieve our desired results in terms of the components, cut shape, speed and accuracy that we need.

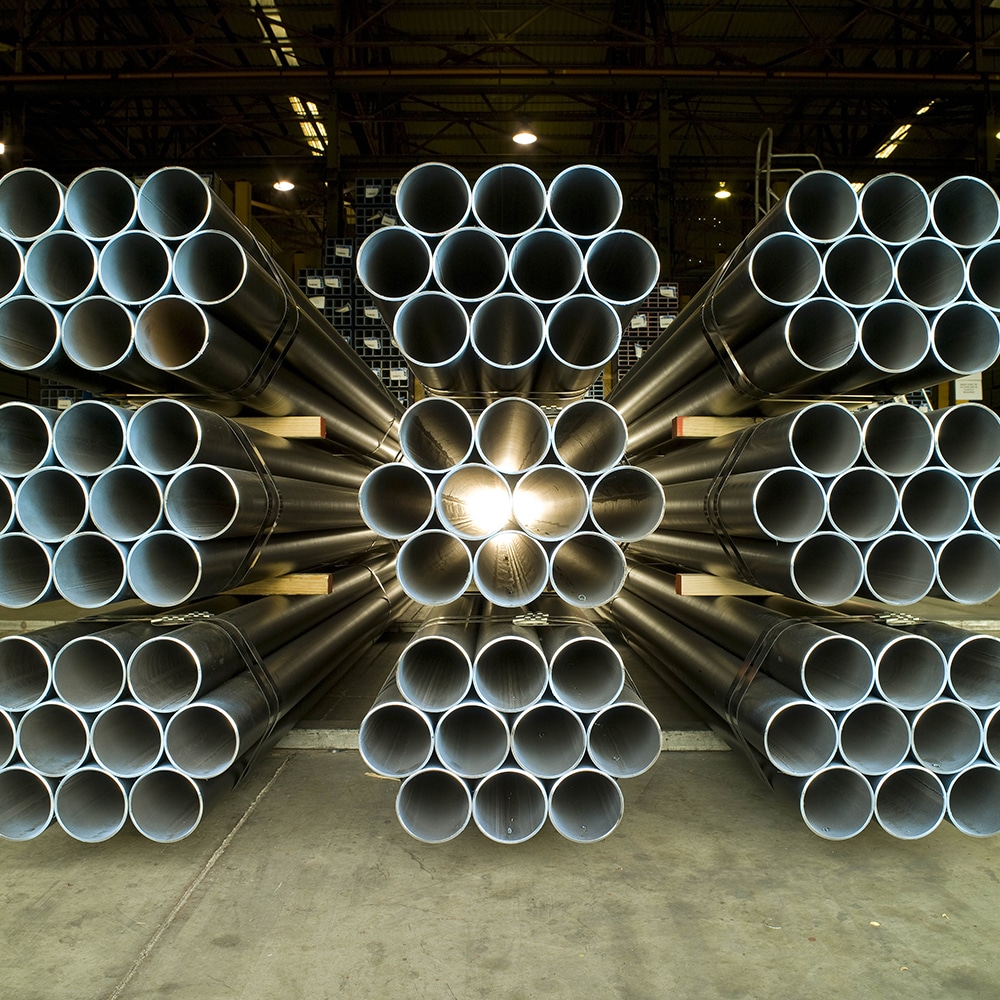

Laser Central were able to offer us a larger tube cutter than anyone else could offer. It has opened a lot of doors for the engineering side of things, including that they use my SOLIDWORKS 3d model to cut from. I’m very confident when I give the file to Laser Central.

We’ve been working with Laser Central since 1999. Throughout this time they have produced for us water treatment solutions like centre-flows and screens.

Our customers care about the same thing we do. Basically, they want a good quality product, and robust solutions in their markets. I think Laser Central are an ethical company. They value their people, and they value their customers.